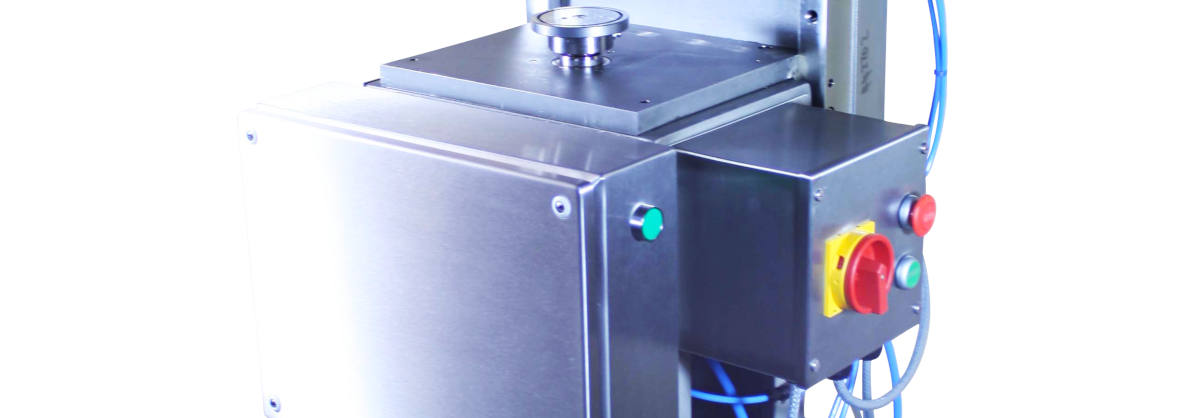

The Innovus 10V model can seamer is used for the double seaming of empty or filled cans in a vacuum. It is a versatile and reliable pneumatically-actuated motor-driven tin closing system.

Industry applications of Innovus 10V

The Innovus 10V has proven a popular model with companies operating low speed production lines. It is employed in a wide range of industrial sectors including dry and processed food and other products in the industrial and pharmaceutical sector which require packing in a low residual oxygen environment to maintain their quality and integrity.

Innovus 10V can seamer features

- Made from all food grade 316 stainless steel

- Ideal for the closing of paperboard, tinplate and aluminium cans

- Can be integrated with Innovus fully automatic linear can sealers

- Features twin button pneumatic actuation to promote operator safety

- Incorporates rotating can seaming with single first and second operation sealing rolls

- High first operation revolutions to maximise double seam integrity

- Uses clockwise can rotation

- Double-row, angular-contact, sealed-for-life roll bearings

- Can be adjusted to take a range of can heights

- Allows for can diameter changes inside thirty minutes

- Uses food grade grease lubrication

- Fitted with a 1.1kW single stage oil-lubricated rotary vane vacuum pump

- Complies fully with European Hygienic Engineering Design Group (EHEDG) food safety guidelines

- CE Mark and EU Declaration of Conformity

Innovus 10V Technical Specifications

- Can diameter range: 50 – 153mm

- Can height range: 50 – 250mm

- Speed: Up to 6cpm

- Can vacuum pressure: To -1000mBar

- Residual oxygen: Potentially < 1 per cent

- AC motor power: 1.1kW

- Air supply pressure: 5 Bar

- Net weight: 170kg